Advantages Of A PCB Board

Electronic circuits have components like resistors, capacitors, transistors and integrated circuits connected together to make products as simple as a doorbell or as complex as a computer.

The earliest circuits were assembled by hand, a tedious method that, in one form, involved manually cutting, trimming and soldering numerous loose, individual wires. Manufacturing in this way was slow and prone to error. In addition, the placement of wires varied from technician to technician, causing difficulties in checking work or correcting mistakes.

The invention of the printed circuit board, also called a PC board or a PCB, led to faster, easier electronic assembly and enabled the creation of circuits with hundreds of components – impossible with manual work.

The typical PCB is constructed with an epoxy-fiberglass board and replaces wires with "traces" photographically printed and then chemically etched on layers of copper. The result is a pattern of conductive lines securely bonded to the board and connecting electronic parts just as wires do.

Types of PCBs

Types of PCBs

Many types of PCBs have been developed for different purposes. An inexpensive toy might use a single-sided printed circuit board because the few components and small number of traces would fit on one side. A larger circuit might need a double-sided PCB, which requires traces on both sides to make all the necessary connections.

Even more complex circuits require additional layers. A four-layer PCB has two inner layers, usually for ground and power connections to components, leaving the outer two layers for the wiring between components. In this case, the inner layers are broad planes of copper for high-quality power distribution and superior shielding against noise – distinct PCB advantages over hand-wired boards.

Desktop and laptop computers have many integrated circuits with thousands of connections between them. They need a multi-layer printed circuit board, which can have more than 40 layers and traces as thin as a human hair. This type of PCB allows a large, complex circuit to occupy a small area.

Although most printed circuit boards are made of epoxy-fiberglass, other materials like phenolic paper or Teflon may be used, instead, to meet the requirements of the product. Typical PCBs are rigid, but they can also be fabricated of thin sheets of temperature-resistant plastic that can be folded to fit in small or unusual spaces.

Designing and Fabricating a PCB

Designing and Fabricating a PCB

Engineers now design PCBs with computers, which help create and check the arrangement of components and the routing of traces between them. The finished design can then be transmitted digitally to a company that specializes in board fabrication.

Because they can be mass-produced at high speed, printed circuit boards cost far less than an equivalent hand-wired board. Unlike for hand-wired boards, machines can rapidly install components on a PCB and solder them all at once.

Additional PCB Advantages

Additional PCB Advantages

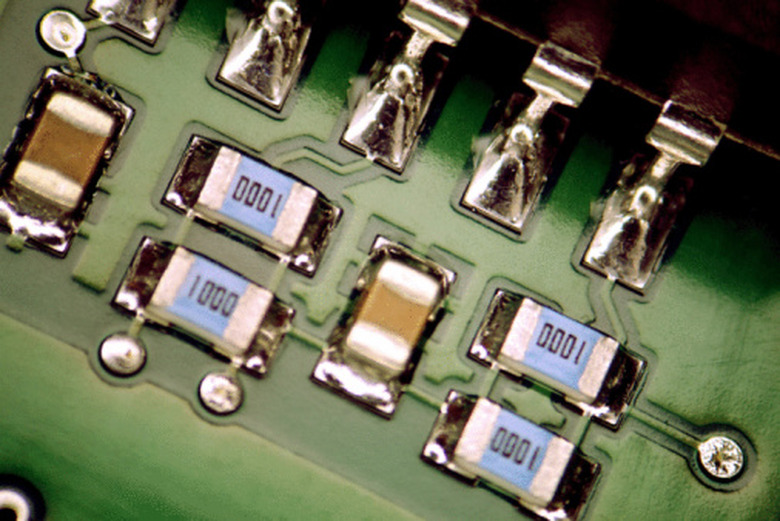

Printed circuit board technology, with high-density connections and thin traces, permits the use of smaller and smaller electronic devices for ever more compact products. At its extreme, passive components like resistors are barely larger than grains of sand; integrated circuits might have a hundred connections packed in a space the size of a fingernail.

Because mass-produced PCBs of the same design are identical, they can be easily tested to diagnose and repair problems. PCBs have clearly defined traces and components that are labeled on the surface of the board, both significant aids to service technicians.

By providing a stable base for components and eliminating the variability caused by manual wiring, printed circuit boards have tremendously increased the reliability of electronic products.

Parts do not move when the board shakes, which is important for PCBs in vehicles like cars or spacecraft. Components can be located in a way that reduces the pick-up of electronic interference between them or from outside sources. Consistent placement of components and traces means consistent performance, critical to all our complex modern devices from smartphones to laptop computers.

Cite This Article

MLA

Lee, H.L.M.. "Advantages Of A PCB Board" sciencing.com, https://www.sciencing.com/advantages-pcb-board-8261204/. 3 September 2019.

APA

Lee, H.L.M.. (2019, September 3). Advantages Of A PCB Board. sciencing.com. Retrieved from https://www.sciencing.com/advantages-pcb-board-8261204/

Chicago

Lee, H.L.M.. Advantages Of A PCB Board last modified March 24, 2022. https://www.sciencing.com/advantages-pcb-board-8261204/