What Are Ball Bearings Used For?

Sometimes the most useful devices in physics and engineering are the simplest ones. Ball bearings show how metal rings can be extremely versatile. As you can see in so many common items such as vehicles, bicycles, skateboards and other machines that involve moving metallic parts, humans have used the power of ball bearings for centuries.

Ball Bearing Uses

Ball Bearing Uses

Imagine sliding across a soft carpet while wearing shoes. It can be difficult because of the friction between the carpet and your shoes, which could be made of anything including leather, plastic, wood or rubber. If you instead wore socks, it'd be much easier because of much less friction between the soft carpet and the materials of the socks. Ball bearings work the same way.

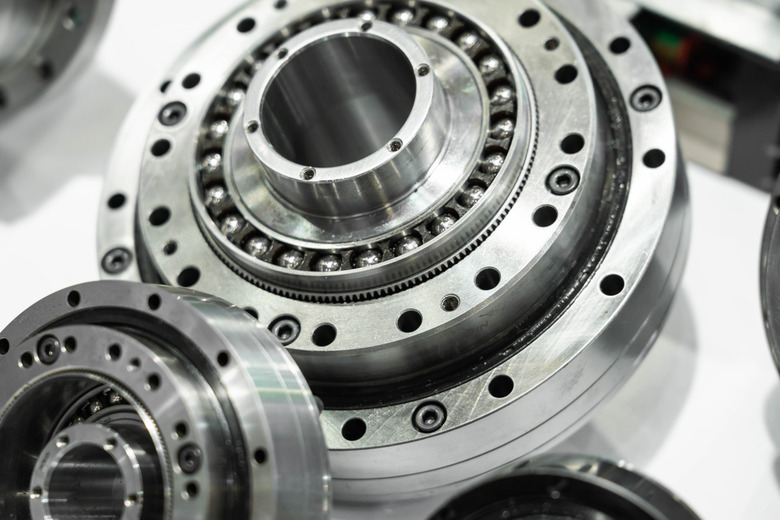

Ball bearings decrease the amount of friction between loads put upon them. They do this because they are metal balls or rollers that move around a smooth metal surface in an inner loop and an outer loop (sometimes referred to as rings). You can learn about the many ball bearing applications through their physics. Ball bearings carry types of load in a radial direction, and these loads apply a perpendicular force to the axis of rotation of the ball bearing.

The sliding of the metallic balls around the loops of the ball bearing create friction between an object and its surface that slows the object down. In some cases the object approaches a stop. This mechanism lets ball bearings have uses in pulley systems or rotational systems that need to be controlled. For instance, the hub wheel of a car uses a radial load from the car's weight and thrust from going around a turn.

In all cases of ball bearings, the balance between thrust and radial load causes ball bearings to reduce friction between the balls in the inner and outer ring and handle the load of the object. Ball bearings take the load and transfer it from the outer ring to the inner ring to let the spheres in the centers of each ring rotate with ease.

Each sphere is connected with the two rings, but only where necessary to reduce the friction between the components of the ball bearing itself. For these reasons, ball bearings are created to reduce friction and ease rotation speed.

Types of Ball Bearings

Types of Ball Bearings

The types of ball bearings differ greatly by their mechanism involved. The most widely used kind is the rigid single row, or radial ball bearing. This design causes the balls to run in deep grooved tracks, and the deep groove ball bearing arrangement lets them bear both radial and axial loads. Sealed versions of ball bearings are permanently lubricated to reduce their maintenance.

Double row ball bearings use two rows of balls. The design gives more rigidity to the motion of the bearing itself. They're found in electric motors, centrifugal pumps and electromagnetic clutches. Some ball bearings align themselves in a way that lets the shaft account for any misalignment at an angle with respect to the housing of the ball bearing.

The angular-contact type of ball bearing has one side of the outer-ring cut off to let more balls insert themselves. These bearings can then hold high amounts of axial loads in one direction as well as use more balls in the bearings themselves. This means engineers use them in pairs in both directions to carry heavy loads, in a setup that makes them angular-contact double row ball bearings. These types of ball bearings vary based on their material as well.

Types of Ball Bearing Material

Types of Ball Bearing Material

Ball bearings vary in material with steel, ceramic or plastic ball bearings for different uses. These types of ball bearings differ in how fast they can operate, what temperatures they can achieve and other properties related to ball bearing uses. Understanding the positives and negatives of each type of material will let you make a wiser decision if you need ball bearings.

Steel Ball Bearings

Steel Ball Bearings

Steel ball bearings use either components that are entirely made of steel or steel alloys with traces of other elements in the composition. They're ideal candidates for handling very heavy weight loads while achieving great rotation speeds when spinning around.

These types of ball bearings can give you very precise measurements because they're manufactured at high levels of precision. Their properties let steel carbon ball bearings have uses in locks, bicycles, roller skates, trolleys and conveyor machines, among others.

The steel ball bearing material can, unfortunately, cause corrosion in the presence of water or gases that change the chemical composition of steel itself. These types of ball bearings can also be very heavy and noisy when they're being used in manufacturing and other environments.

Steel ball bearings can be very expensive, and engineers also need to constantly lubricate steel metals to keep them working efficiently. If they aren't properly maintained, they can cause bearing failure and won't reach the end of their intended lifetime.

Manufacturers create and sell steel ball bearings in different styles. You can buy steel balls with higher amounts of carbon that are exposed to heat treatments or have been hardened through other methods. Variations in carbon content among steel ball bearings affect their properties. Low-carbon steels are found in applications that need to be resistance to corrosion, but not necessarily have surface that's hardened.

While low-carbon steel material can be used in the linear shafting of a ball bearing, they're not great for contact between the balls themselves. They're generally used with a polymer to prevent damage in these cases. Steel ball bearings with moderate amounts of carbon are strong, water-resistant and tough, and these features make them suitable for gears, axles, studs and other machine components. High-carbon steels are the strongest and hardest while resisting corrosion.

Ceramic Ball Bearings

Ceramic Ball Bearings

Ceramic ball bearings are typically created as "hybrids" that use the outer ring, inner ring and cage built of steel with the balls themselves made of ceramic. The ceramic properties let them operate at fast rotations per minute while keeping their operating temperature cool and limiting how much noise they create.

These hybrid ceramic-steel designs are damaged by corrosion, but the ceramic balls themselves are less prone to corrosion than steel materials, and are more durable and more lightweight than steel ball bearings.

These types of ball bearings can be used in electrical applications where steel ball bearings can't because ceramic ball bearings are non-conductive, but they're also very expensive. Ceramic ball bearings can withstand high temperatures, letting them operate at higher speeds. The prices for some of these ball bearings may be generally expensive, but you can find inexpensive versions of them, too.

The ceramic material of these ball bearings gives them weights of less than 40% than those of steel ball bearings. Engineers typically manufacture them using ceramic silicon nitride to cause these chemical and physical properties to occur. They're used in angular bearings, thrust bearings, pillow block bearings, needle bearings and roller bearings. Ceramic materials may be stronger than steel, but they're generally stiffer as ball bearing material.

Polishing ceramic steel balls uses a magnetic field with a plasma stream. This method of production gives them higher rates of rotation than steel ball bearings. They're electrically insulating, meaning they don't conduct electricity, so they don't fail if current is passed through them, and they can function without being lubricated like steel ball bearings must be.

Plastic Ball Bearings

Plastic Ball Bearings

Recent innovations have produced plastic ball bearings that use plastic rings and a plastic cage, and can be bought in the form of balls made from plastic, glass or stainless steel. The most common ball material with this type of ball bearing is the stainless steel ball. They're the most affordable option, but they're also heavier than plastic or glass kinds. They can also become magnetic easily, which can disrupt the motion and physics of nearby materials.

Plastic ball bearings with glass balls are great choices when you can't use metal. They have high chemical resistance and have lower weights than steel balls do. Plastic balls for the plastic ball bearings weigh even less and offer wear resistance as they're used over time. Most plastic ball bearings are self-lubricating, lightweight and resistant to corrosion while operating quietly.

These types of ball bearings unfortunately don't withstand high temperatures as well as other ball bearings do and can't handle as high loads as them sometimes.

References

- HCH Bearing Americas: How Ball Bearings Work

- Bearing Tips: A guide to ball bearing materials

- Abbott Ball Company: Carbon Steel Balls

- Mishumi Mech Lab: The Difference Between Carbon Steels

- Engineers Edge: Ceramic Bearings Design, Engineering and Review

- The Electronic Chronicles: Taking a look at Ceramic Bearings

- Popular Mechanics: Genius Greaseless Bearings Spin With 10 Times Less Friction

Cite This Article

MLA

Ather, S. Hussain. "What Are Ball Bearings Used For?" sciencing.com, https://www.sciencing.com/ball-bearings-used-for-5733387/. 22 September 2019.

APA

Ather, S. Hussain. (2019, September 22). What Are Ball Bearings Used For?. sciencing.com. Retrieved from https://www.sciencing.com/ball-bearings-used-for-5733387/

Chicago

Ather, S. Hussain. What Are Ball Bearings Used For? last modified August 30, 2022. https://www.sciencing.com/ball-bearings-used-for-5733387/