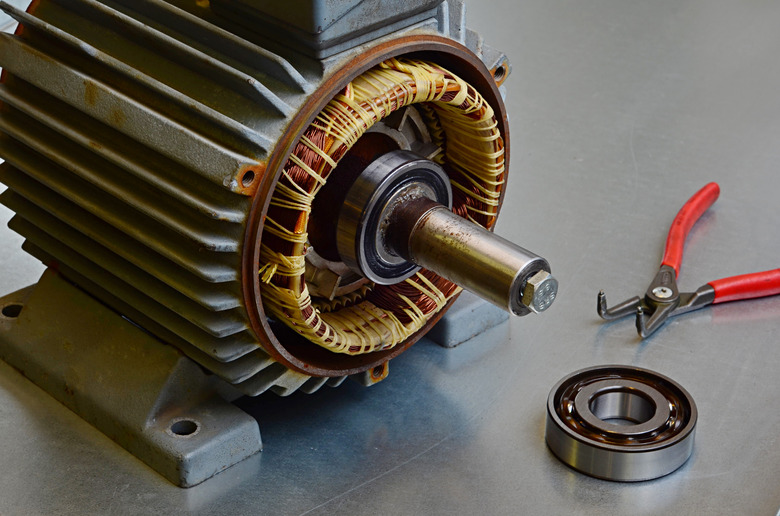

Can You Repair A Burned-Out Electric Motor?

If an electric motor operates at too high a voltage, excess current flowing through the windings can cause them to become hot and burn out. While it is normally not practical to repair small, direct current (DC) motors that have burned out, other motors can be repaired by rewinding.

Short Circuit

Short Circuit

When a motor burns out, a short circuit occurs in the windings and the motor ceases to turn. You can test for a short circuit by checking the resistance of the windings with an ohmmeter; a reading of 0 ohms (Ω) indicates a short.

Winding Removal

Winding Removal

The first step in rewinding a motor is to remove the old winding. Commercially, this is done by baking the stationary part of a motor in an oven at 650 degrees Fahrenheit for several hours.

Rewinding Coils

Rewinding Coils

The new windings are wound on a coil winding machine, under the supervision of a technician, who controls the tension, layering and number of turns. The newly wound coil is dipped in epoxy varnish and, once again, baked in an oven to complete the process.

References

- Maintenance World: Maintenance and Troubleshooting of Electric Motors

- "Robot Builder's Sourcebook"; Gordon McComb; 2002

Cite This Article

MLA

Dunning, David. "Can You Repair A Burned-Out Electric Motor?" sciencing.com, https://www.sciencing.com/can-repair-burnedout-electric-motor-7893438/. 13 March 2018.

APA

Dunning, David. (2018, March 13). Can You Repair A Burned-Out Electric Motor?. sciencing.com. Retrieved from https://www.sciencing.com/can-repair-burnedout-electric-motor-7893438/

Chicago

Dunning, David. Can You Repair A Burned-Out Electric Motor? last modified March 24, 2022. https://www.sciencing.com/can-repair-burnedout-electric-motor-7893438/