What Is The Chemical Formula Of Steel?

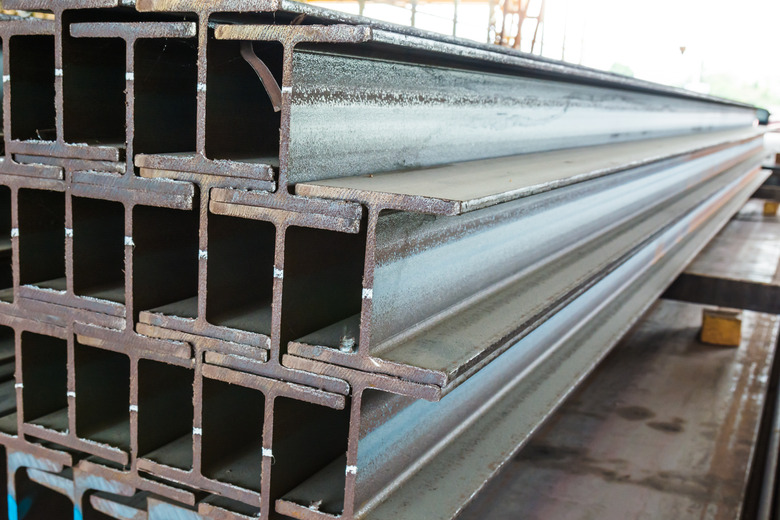

When some people think of steel, they may envision a skyscraper being assembled using massive riveted beams, while other people may picture the body and engine of a classic car at a car show. Indeed, steel is present in many things that people use every day. Understanding the chemical makeup of steel is useful when determining what sort of steel should be used, as well as in what application to use it. Because steel is a mixture rather than a chemical compound, it doesn't have a set chemical compound formula. When you are looking for the right kind of steel to use, the additives determine which steel is the best choice for your purpose.

TL;DR (Too Long; Didn't Read)

Steel is a mixture of iron and carbon fused together with one or more other metals or nonmetals. Because steel is a mixture rather than a chemical compound, steel does not have a set chemical compound formula. The naming convention for steel depends upon the steel's composition—what is mixed in with the iron—such as carbon steel or tungsten steel.

Iron and Carbon Play a Big Role

Iron and Carbon Play a Big Role

Iron is a moderately reactive metal that is prone to combining chemically with nonmetals such as oxygen and carbon. When iron is mined or otherwise found in nature, it is typically found as a naturally occurring mineral. When iron ore is heated in the presence of a reducing agent such as carbon monoxide, it produces metallic iron. From there, iron is further refined to create an iron-carbon alloy that can be used to make the material we know as steel.

The iron-carbon alloy is the base material of steel. The proportion of carbon in the alloy is usually around 0.15 to 0.30 percent, and it determines the initial strength and ductility – the ability to be drawn into wire or to be worked – of the alloy. When the alloy has a larger proportion of carbon in it, the steel is stronger. However, it is less ductile than a lower-carbon alloy.

After the iron-carbon alloy has been refined to the desired ratio of carbon to iron, additional materials may be added to enhance the characteristics of the final steel alloy. For example, if the final alloy is stainless steel, chromium and manganese are added to the mixture.

Enhancing Steel

Enhancing Steel

While some forms of steel, such as mild steel, may consist of nothing more than iron and carbon, several important chemical elements are used to create structural-grade steel. For example, manganese and niobium are used to provide extra strength to steel, while chromium, nickel or copper are added to reduce the steel's susceptibility to rust and corrosion. Similarly, molybdenum, vanadium, tungsten or titanium may be added to enhance other aspects of steel to improve performance. Steels may be further processed by rustproofing using galvanization (coating with zinc, often by immersion into molten zinc) or electroplating (depositing a material coating on the surface using an electrical current).

Cite This Article

MLA

Sandoval, David. "What Is The Chemical Formula Of Steel?" sciencing.com, https://www.sciencing.com/chemical-formula-steel-5718809/. 11 April 2018.

APA

Sandoval, David. (2018, April 11). What Is The Chemical Formula Of Steel?. sciencing.com. Retrieved from https://www.sciencing.com/chemical-formula-steel-5718809/

Chicago

Sandoval, David. What Is The Chemical Formula Of Steel? last modified August 30, 2022. https://www.sciencing.com/chemical-formula-steel-5718809/