What Is Electrolytic Copper?

Electrolytic copper has undergone refining or purification by electrolysis. Purification by electrolysis represents the easiest method of achieving purity levels of 99.999 percent in copper, according to Science Clarified.

Electrical Equipment

Electrical Equipment

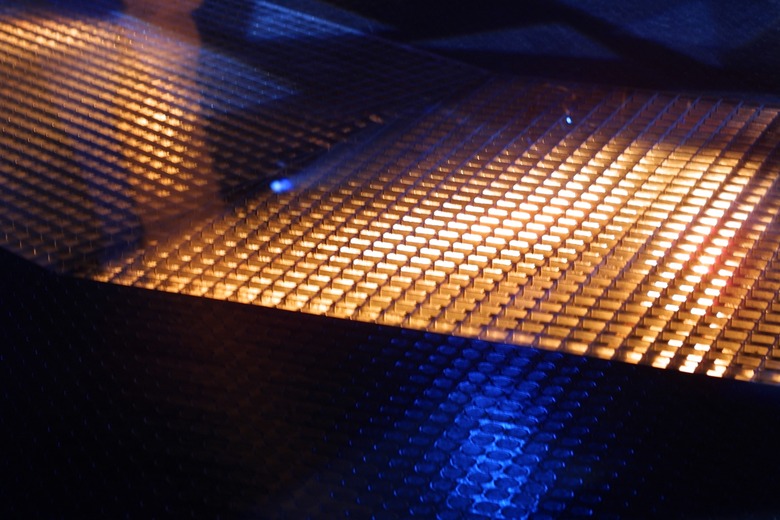

Electrolysis enhances the qualities of copper as an electrical conductor. Electrical equipment often contains electrolytic copper, according to Science Clarified. Copper also is easily drawn and formed into wires.

Copper Ores

Copper Ores

Copper most commonly exists in chalcopyrite and sulphide ores. Silicate, sulfate and carbonate ores also contain copper. The low percentage of copper in these ores makes it necessary to concentrate them before electrolysis, according to Chemguide. The methods used to concentrate copper ores include heating in a furnace or reacting them with sulfuric acid.

Electrolysis of Copper

Electrolysis of Copper

Electrolysis uses an anode that contains the impure copper that results from ore concentration. The cathode consists of pure copper, titanium or stainless steel. The electrolyte solution consists of copper sulfate, according to Science Clarified. An electric current causes copper ions from the anodes to enter the solution and become deposited onto the cathode. Impurities either fall away and form sludge or stay in solution. The cathode gets bigger as pure copper forms on it, while the anode shrinks.

References

Cite This Article

MLA

Lee, Lexa W.. "What Is Electrolytic Copper?" sciencing.com, https://www.sciencing.com/electrolytic-copper-6930623/. 24 April 2017.

APA

Lee, Lexa W.. (2017, April 24). What Is Electrolytic Copper?. sciencing.com. Retrieved from https://www.sciencing.com/electrolytic-copper-6930623/

Chicago

Lee, Lexa W.. What Is Electrolytic Copper? last modified March 24, 2022. https://www.sciencing.com/electrolytic-copper-6930623/