What Are The Functions Of Parts In An Electric Motor?

Electric motors rely on electromagnetic induction, a phenomenon discovered in the early 1800s by physicist Michael Faraday. He found that moving a magnet through a toroid, around which he had wrapped a conducting wire, generated an electric current in the wire. Electric motors use this idea in reverse. When a current passes through a coil, the coil becomes magnetized, and if it's attached to a shaft and suspended in the field generated by a permanent magnet, the opposing magnetic forces create enough force to turn the shaft. Connecting the shaft to a gear mechanism makes it capable of doing work, and adding bearings reduces friction and increases the efficiency of the motor.

TL;DR (Too Long; Didn't Read)

The main parts of an electric motor include the stator and rotor, a series of gears or belts, and bearings to reduce friction. DC motors also need a commutator to reverse current direction and keep the motor spinning.

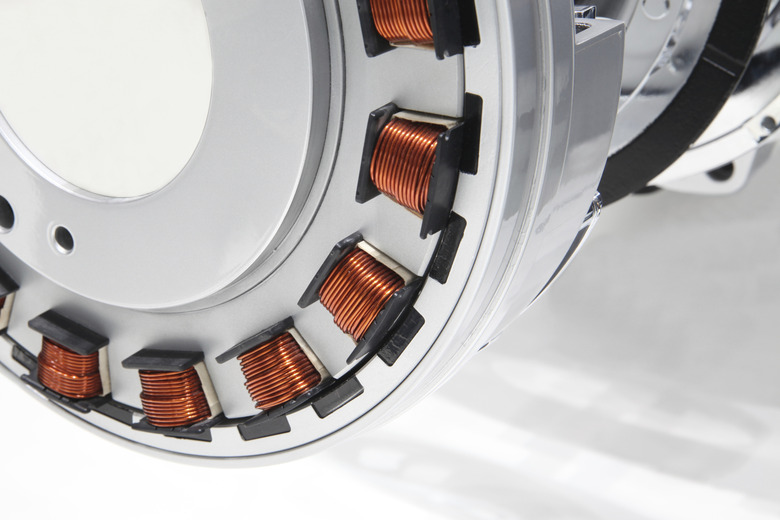

The Stator, Rotor, Brushes and Commutator

The Stator, Rotor, Brushes and Commutator

Rather than using a permanent magnet, modern commercial electric motors usually rely completely on electromagnets. A series of small coils arranged in a circular arrangement forms the stator, and these coils generate a standing magnetic field. A a separate coil wound around an armature and attached to a shaft forms the rotor, which spins inside the field. Because you can't attach wires to a spinning coil, the rotor usually incorporates metallic brushes that remain in contact with a conducting surface on the stator. This surface, along with the stator windings, are connected to power terminals located on the motor housing.

When you turn on the power, electricity flows into the field coils to create a standing magnetic field. It also flows through the brushes and energizes the armature coil. DC motors, such as those that run on a battery, also include a commutator, which is a switch attached to the rotor shaft that reverses the electric field with every half spin of the rotor. This field reversal is necessary to keep the rotor spinning in one direction.

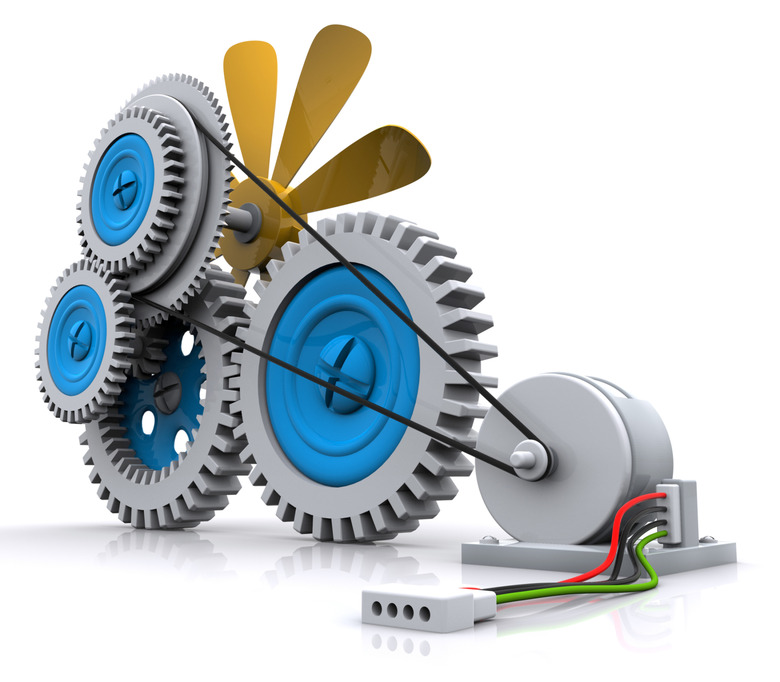

Gears and Belts

Gears and Belts

By itself, a spinning motor shaft isn't very useful, unless you want to use it for drilling or for spinning a fan blade. Most motors incorporate a system of gears and/or drive belts to convert the energy of the spinning shaft into useful movement. The configuration of the belts or gears can increase rotational speed on an adjacent shaft, which results in a reduction of power, or it can increase the power while reducing rotational speed. Worm-drive gears can change the direction of rotation by 90 degrees. Gears and belts make it possible for a single motor to perform a variety of functions simultaneously.

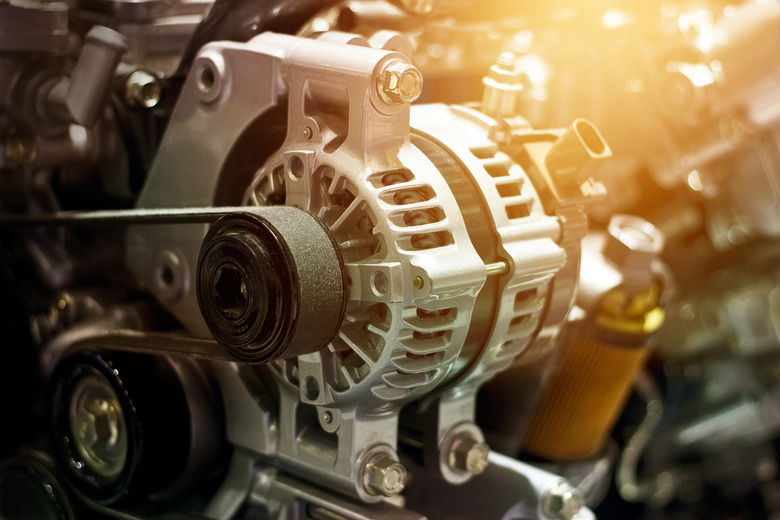

Bearings to Reduce Friction

Bearings to Reduce Friction

The larger the motor, the more friction is generated between the moving parts. This frictional force opposes the movement of the rotor, reducing the efficiency of the motor and ultimately wearing down the parts. Most motors have bearings between the stator and the rotor to keep the rotor centered and minimize the air gap. Smaller motors have ball bearings while large motors employ roller bearings. Bearings need periodic lubrication, which along with servicing and cleaning of the stator windings and rotor brushes, is an important maintenance procedure.

Cite This Article

MLA

Deziel, Chris. "What Are The Functions Of Parts In An Electric Motor?" sciencing.com, https://www.sciencing.com/functions-parts-electric-motor-7202983/. 17 April 2018.

APA

Deziel, Chris. (2018, April 17). What Are The Functions Of Parts In An Electric Motor?. sciencing.com. Retrieved from https://www.sciencing.com/functions-parts-electric-motor-7202983/

Chicago

Deziel, Chris. What Are The Functions Of Parts In An Electric Motor? last modified August 30, 2022. https://www.sciencing.com/functions-parts-electric-motor-7202983/