How To Design Compressed Air Systems

Things Needed

- Compressor discharge piping

- Thermometer

- Liquid filled pressure gauge

- Thermowell

- Drip legs

- Automatic drain tap

- Low point drain

The basic purpose of compressed air systems is to deliver the compressed air to the places where it is going to be used. The compressed air has to be delivered with the right amount of volume, pressure and quality so that the components that use the air can be powered in the correct manner. A compressed air system that is not designed properly will increase the costs of energy, lower production efficiency and also lead to equipment failure. Most compressed air systems consist of a demand and supply side. The supply side is made up of the compressors and air treatment, while the demand side is made up of the storage and distribution equipments.

Step 1

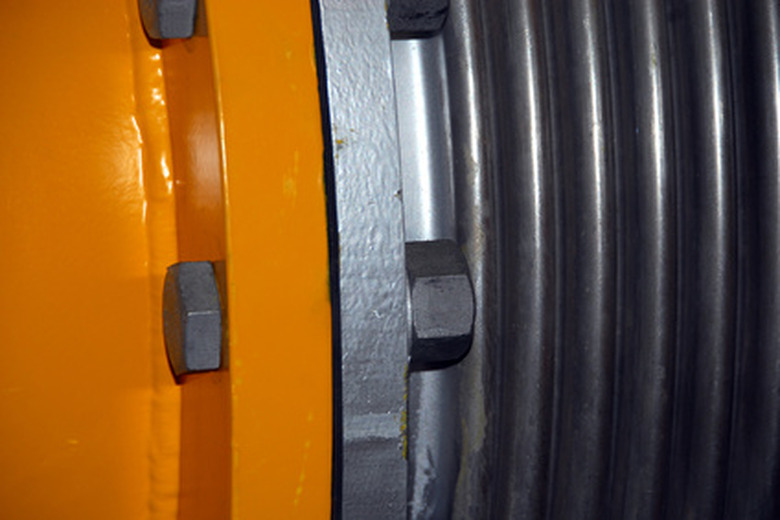

Install the compressor discharge piping, noting that the pipe needs to be able to withstand very high temperatures.

Step 2

Install a thermometer, liquid-filled pressure gauge and a thermowell in the discharge air line before the aftercooler.

Step 3

Install drip legs at all the low points in the entire system. Install an automatic drain tap at the end of the drip leg. This step deals with condensation control. A drip leg is a pipe extension from below the airline that will be used for collecting condensation in the pipe.

Step 4

Install a low point drain in the discharge pipe before the aftercooler to get rid of oil or cooling water.

Step 5

Slope the main header pipe downward in the direction of the flow of compressed air. An efficient loop design of a compressed air system will allow the airflow to take place in two directions. This will lower the pipe length to almost half and will reduce the occurrence of pressure drop. Many experts also recommend the installation of a balance line to provide an additional source of air.

TL;DR (Too Long; Didn't Read)

Most of the supplies can be picked up at your local home and hardware superstore.

Overall, any compressed air system will be made up of the following processes: compression, cooling, storage and equipment for distribution. The type of compressed air system installed will be dependent on the size, cost and reliability requirements an industrial process will have from that compressed air system.

References

- Designing Your Compressed Air System: Kaeser Compressors Guide

Cite This Article

MLA

Webb, Erin. "How To Design Compressed Air Systems" sciencing.com, https://www.sciencing.com/how-7604403-design-compressed-air-systems/. 7 August 2017.

APA

Webb, Erin. (2017, August 7). How To Design Compressed Air Systems. sciencing.com. Retrieved from https://www.sciencing.com/how-7604403-design-compressed-air-systems/

Chicago

Webb, Erin. How To Design Compressed Air Systems last modified March 24, 2022. https://www.sciencing.com/how-7604403-design-compressed-air-systems/