How Does A Lock-Out Relay Work?

Personnel Safety

Personnel Safety

Lock-out relays are generally installed on equipment that requires a periodic inspection. This inspection can be either for maintenance purposes or the cleanliness of the machinery for food preparation. Daily inspections are routinely carried out in the food industry by the U.S. Department of Agriculture. Under the regulations for inspection of the machines, the electrical source or control power must be shut off by a central location controlled by a key. This key is then locked in a separate box so that during the inspection no personnel can start or operate the machines.

The Relay

The Relay

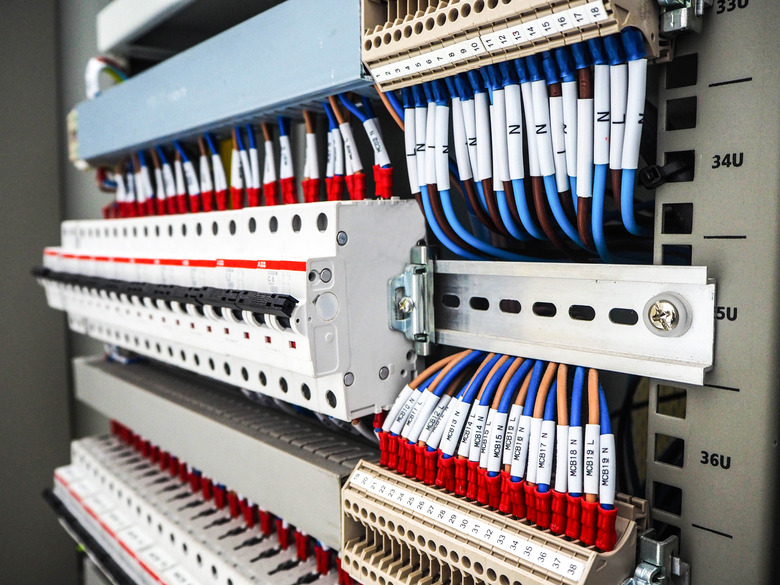

All electrical machines are started and stopped by an input signal generated by a low-voltage source. This source generally comes from a single location for safety purposes. This allows for a series of emergency stop (e-stop) switches to be placed on the process line so the entire line can be shut down in case of emergency. A lock-out relay is generally placed in line before or after the e-stop switch so the power can be shut off at one central location. This relay is powered by the same electrical source as the control power and is operated by a key lock switch. The relay itself may have up to 24 contact points within the unit itself. This allows the control power for multiple machines to be locked out by the turn of a single key switch.

The Control Voltage

The Control Voltage

The power that operates not only the individual start and stop devices but also the lock-out relay and e-stop is called the control voltage. This voltage will be much lower than the main power that runs the motors and machines in an industrial setting. Typically, common control voltage is 120 volts alternating current (VAC). Although much lower than the operational voltage of 480 VAC, 120 VAC can still deliver a nasty shock if used in wet locations such, as the food industry. Lock-out relay circuits and control voltage for wet locations are generally a 24-volt direct current (VDC) power source. This low DC voltage does not create a major shock hazard and is easily controlled for safety by a fast-acting fuse that disables the power in the circuit due to an accidental short to ground. The 24 VDC power is generally the industrial standard for controlling equipment by a lock-out relay system in a wet environment.

Control of Keys

Control of Keys

The lock-out relay is activated by a key switch. This key switch is generally controlled by a singular pair of keys. These keys are kept locked in a red-colored lock-out box. This lock-out box will generally have two locks placed on the container so both parties are present when the box is opened to activate the lock-out relay. Once the relay is under operation to remove power from the machinery, those keys are placed back in the box and secured until the inspection is completed. After a successful inspection, the system is then re-energized so the processing may begin.

Cite This Article

MLA

Bayne, G.K.. "How Does A Lock-Out Relay Work?" sciencing.com, https://www.sciencing.com/how-does-4913736-lockout-relay-work/. 16 April 2009.

APA

Bayne, G.K.. (2009, April 16). How Does A Lock-Out Relay Work?. sciencing.com. Retrieved from https://www.sciencing.com/how-does-4913736-lockout-relay-work/

Chicago

Bayne, G.K.. How Does A Lock-Out Relay Work? last modified March 24, 2022. https://www.sciencing.com/how-does-4913736-lockout-relay-work/