How A Hydraulic Relief Valve Works

Hydraulics Make Life Easier

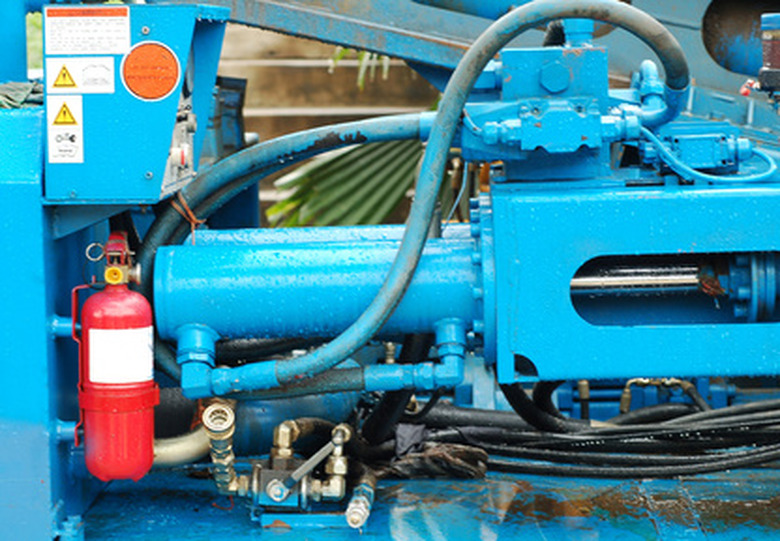

Hydraulic circuits are used in everyday life. If you drive a vehicle, chances are the steering is operated by hydraulics for easy turning of the front wheels. Farm tractors use a large hydraulic circuit to power attachments and perhaps even move the large rear wheels. You may even have a hydraulic log splitter to break down the winter's worth of wood to fit in the fireplace or wood stove. Regardless of the application, hydraulics are all basically the same. A fluid pump is used to increases the pressure of the hydraulic oil. This oil, under pressure, is employed to move either a motor or a long cylinder to perform work. If for some reason the hydraulic pump fails and the pressure becomes too great, the excess pressure must be released before damage or personnel injury occurs. A pressure relief valve is used just for this situation.

Fixed Valves

Fixed Valves

Pressure relief valves are used to open when the hydraulic system reaches an unsafe or excessive level. Without the use of the valve, the high pressure could damage hoses or literally "blow" apart hydraulically driven motors or cylinders. Fixed pressure relief valves are generally used as a safety device for any excessive pressure situation. Some safety valves are made as a one-time device and must be replaced when they have performed the task. Others can be reused time and time again for releasing the high-pressure fluid. Some fixed pressure release valves may allow the fluid to be expelled back into the reservoir tank for reuse, while smaller hydraulic systems may release the fluid to outside of the sealed system. In any case, if the high-pressure fixed safety relief valve operates, this can indicate a failure of the hydraulic system.

Adjustable Relief Valves

Adjustable Relief Valves

Hydraulic systems that employ an adjustable relief valve are part of a working system. Many large hydraulic presses can utilize this type of valve as a control mechanism to apply only so much pressure for bending or pressing metal. The adjustable relief or bypass valve allows a certain pressure to be reach in the sealed system. When this pressure is reached, the hydraulic fluid is released back into the reservoir tank and the fluid is reused. This allows the pressure to be maintained at a particular gauge reading for a proper amount of force to be exerted to the cylinders. Generally, all hydraulic presses that press or bend metal have some type of adjustable pressure relief valve for the operation of the cylinders.

Cite This Article

MLA

Bayne, G.K.. "How A Hydraulic Relief Valve Works" sciencing.com, https://www.sciencing.com/how-hydraulic-relief-valve-works-5005890/. 24 April 2017.

APA

Bayne, G.K.. (2017, April 24). How A Hydraulic Relief Valve Works. sciencing.com. Retrieved from https://www.sciencing.com/how-hydraulic-relief-valve-works-5005890/

Chicago

Bayne, G.K.. How A Hydraulic Relief Valve Works last modified March 24, 2022. https://www.sciencing.com/how-hydraulic-relief-valve-works-5005890/