How Pneumatic Timers Work

Pnumetic Timers: Pistons, Valves, and the Flow of Air

Pnumetic Timers: Pistons, Valves, and the Flow of Air

Pnuematic timers are used in areas where the use of an electrical current is undesirable or dangerous. (Many oil refineries use pneumatic timers instead of electric clocks. An electric spark in such a manufacturing establishment can easily start a fire.)

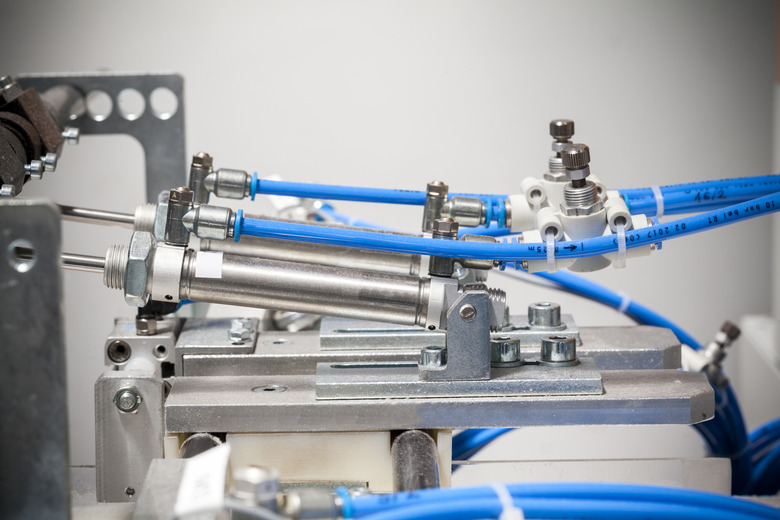

How these devices operate can be a little confusing, but the most basic pneumatic timer involves a piston and a control valve. It is necessary to hook all pneumatic equipment up to an air supply for proper operation.

An air supply slowly pushes the piston towards the end of the chamber. A small valve on the other end controls the flow of air. The piston will eventually reach its intended destination. It will take the piston some time before it accomplishes this task however. There are other types of air timers that use a different controlling mechanism, but the piston chamber is used most often. (Creating or filling a vacuum is another common timer control technique.)

How the Piston Gets Slowed

How the Piston Gets Slowed

Some doors contain a mechanism that prevents a door from being slammed. When too much air builds up behind the door, the door will slow down until and close at a more manageable pace. How the piston works is similar. The valve at the end of the piston chamber prevents the air from escaping too quickly, and thus allows a precise time to be set by the user of a pneumatic timer

What Pnuematic Timer Controls Allow

What Pnuematic Timer Controls Allow

The controls for the timer allow the user to set up how much time will pass before the piston opens the chamber. The dial, essentially, controls how far the valve opens when the timer is in operation. Thus, industries can get precise timing without relying on electrical timing devices.

Cite This Article

MLA

Writer, Contributing. "How Pneumatic Timers Work" sciencing.com, https://www.sciencing.com/how-pneumatic-timers-work-4965786/. 30 April 2009.

APA

Writer, Contributing. (2009, April 30). How Pneumatic Timers Work. sciencing.com. Retrieved from https://www.sciencing.com/how-pneumatic-timers-work-4965786/

Chicago

Writer, Contributing. How Pneumatic Timers Work last modified March 24, 2022. https://www.sciencing.com/how-pneumatic-timers-work-4965786/