What Is An IC Socket?

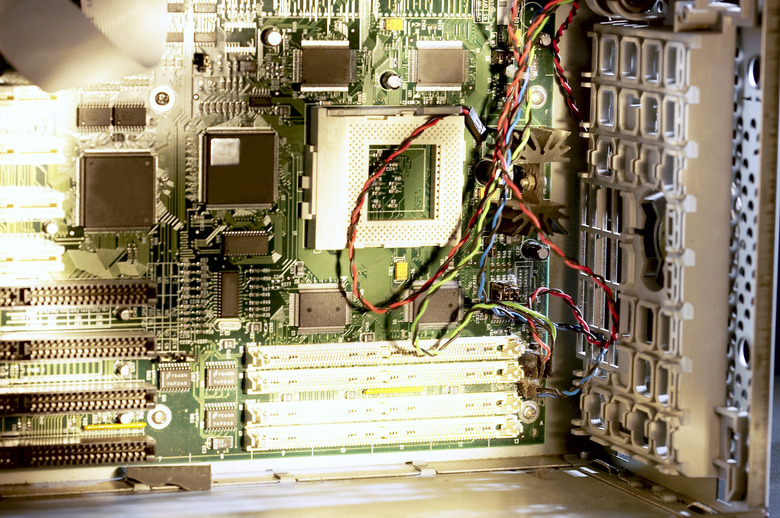

Integrated circuits, or ICs, are the chips used in almost all modern electrical devices. Most production devices use chips soldered directly to the printed circuit board, as the chips never need to be removed. Some applications, however, use IC sockets, which allow chips to be inserted and removed without the use of a soldering iron.

Purpose

Purpose

Programmable chips such as EPROMs or microcontrollers are placed in IC sockets during prototyping, allowing the devices to be quickly removed from the circuit for programming, then reinserted for testing. Some integrated circuits are extremely sensitive, and may be damaged by the heat from soldering, so are placed in IC sockets for protection and easy replacement if failures occur. Computer motherboards use a socket for the CPU, allowing you to choose your own processor for the board and upgrade the CPU.

DIL Sockets

DIL Sockets

Dual in-line sockets, or DILs, are the cheapest type of IC socket, and are available with different numbers of pins to match the target IC. The sockets are soldered to the circuit board in place of the chip, and the chip is then pushed gently into the socket. Spring contacts in the socket make an electrical connection to each leg of the integrated circuit. Most sockets can be mounted end-to-end, allowing two smaller sockets to make one large one — for example, two 8-pin sockets could be placed end-to-end to make a 16-pin socket.

Turned Pin DIL Sockets

Turned Pin DIL Sockets

Turned pin sockets are slightly more expensive than standard DIL sockets, but offer a better electrical connection with lower resistance and higher reliability. The turned pins are of a higher quality and often gold-plated, allowing the socket to tolerate higher voltages and currents than spring contact pins. The turned pins offer four points of contact on the legs of the target IC, compared to two points with spring contact pins. Usually used in devices such as chip programmers and similar, turned pin sockets cope better with chips being inserted and extracted multiple times.

ZIF Sockets

ZIF Sockets

One of the main drawbacks to DIL sockets is the force required to insert the chip into the socket, which has to be a tight fit to create the best electrical connection. If too much force is used, or a chip is removed and inserted multiple times, its legs can buckle and bend instead of sliding into the socket. In some cases, you can bend the legs back into shape, but being so thin, they are easy to snap off entirely, rendering the chip useless. Zero insertion force, or ZIF, sockets resolve this problem by using a clamp system. When the clamp is opened using a lever, a chip can be placed in the socket without any force required, as the holes in the socket are larger than the legs on the chip. When the lever is locked into the operating position, contacts on either side of the IC legs are squeezed together to lock the IC firmly in place, providing a good electrical connection. ZIF sockets are more expensive than standard or turned pin DIL sockets, but can save time in use and prevent expensive IC damage.

Cite This Article

MLA

Downes-Powell, Gareth. "What Is An IC Socket?" sciencing.com, https://www.sciencing.com/ic-socket-10029906/. 24 April 2017.

APA

Downes-Powell, Gareth. (2017, April 24). What Is An IC Socket?. sciencing.com. Retrieved from https://www.sciencing.com/ic-socket-10029906/

Chicago

Downes-Powell, Gareth. What Is An IC Socket? last modified March 24, 2022. https://www.sciencing.com/ic-socket-10029906/