How To Measure Sheave Diameter

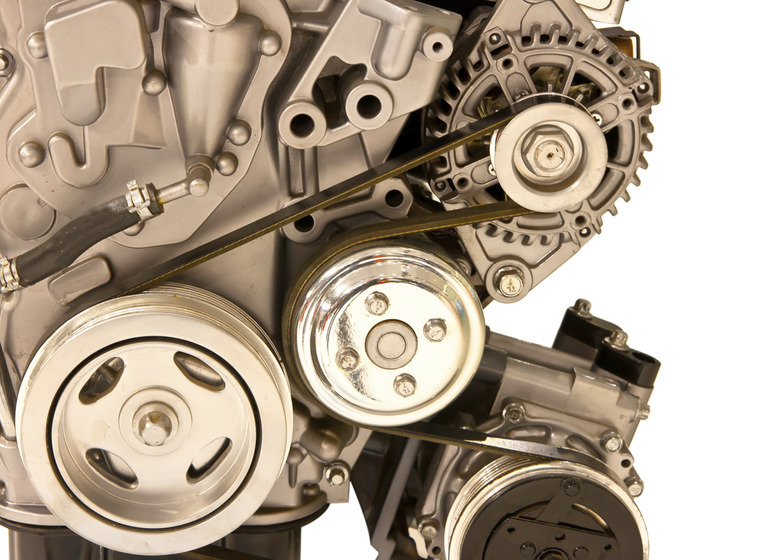

Sheaves, the circular parts of pulleys, carry a belt around a shaft. The belt transmits power to or from one or more other shafts. Knowing the diameter of a sheave matters because a shaft's speed will vary according to its sheave's diameter — in one rotation, a larger sheave will carry a greater length of belt, so the shaft turns more slowly. You can easily determine the outside diameter, but what about the smaller inside diameter? Here are some methods you can try.

Use a String to Measure the Inside Diameter

Step 1

First, we should go over the difference between outside diameter and inside diameter. The outside diameter (abbreviated as OD) is the distance across the whole disc of the sheave– this can be easily measured by placing a ruler on the side of the sheave and simply measuring the diameter. The smaller inside diameter (abbreviated as ID) is the diameter of the circle created by the bottom of the groove of the sheave. The ID determines how much belt moves with one rotation of the sheave — although it isn't always that simple because some belts are designed to wedge into the angled walls of the groove, and not touch against the bottom of the groove.

Step 2

Wrap the string at least twice around the inside of the groove, so it's snug in the bottom and it passes itself.

Step 3

Use the marker to make a single mark which touches each wrap of the string.

Step 4

Remove the string and lay it out straight. You should find marks which are separated by a distance equal to the circumference of the ID. Use the ruler to measure this distance. For example, suppose your marks measure 251mm apart.

Step 5

Compute the ID from the circumference by dividing the circumference by Pi. Dividing 251 by 3.1416 gives 79.895594 – round it up to 80, and you've determined that the ID is 80mm.

Use a Ruler to Measure the Sheave

Step 1

Begin by determining the OD. This is simple — lay the ruler's edge across the center of the sheave and measure the diameter. With that measurement, you can calculate the ID by measuring the depth of the groove. Following the same example as before, suppose you measure 100mm across the sheave – that's the OD.

Step 2

Place the end of the ruler in the bottom of the groove to measure the depth of the groove compared to the rim. This value will be half of the difference between OD and ID. Suppose you measure the depth as 10mm.

Step 3

Double the depth of the groove, and subtract that value from the OD. The difference is the ID. In this example, that's 10mm x 2 = 20mm, so 100mm – 20mm gives you the same 80mm ID.

Things Needed

- Sheave

- String

- Marker pen

- Metric ruler

- Calculator

TL;DR (Too Long; Didn't Read)

When measuring the OD, make sure the edge of the ruler crosses the exact center of the sheave. If it doesn't cross the center, the value you measure will be less than the actual OD.

When choosing a ruler, make sure it doesn't have any extra length before the beginning of the first millimeter.

Warning

Rotating drive belt assemblies are very dangerous because they can pinch something between the belt and a sheave. Never allow your fingers, hair, clothing, or any object to contact a moving belt or sheave.

Cite This Article

MLA

Silbajoris, Alex. "How To Measure Sheave Diameter" sciencing.com, https://www.sciencing.com/measure-sheave-diameter-7511938/. 24 April 2017.

APA

Silbajoris, Alex. (2017, April 24). How To Measure Sheave Diameter. sciencing.com. Retrieved from https://www.sciencing.com/measure-sheave-diameter-7511938/

Chicago

Silbajoris, Alex. How To Measure Sheave Diameter last modified March 24, 2022. https://www.sciencing.com/measure-sheave-diameter-7511938/