Motor Rewinding Procedures

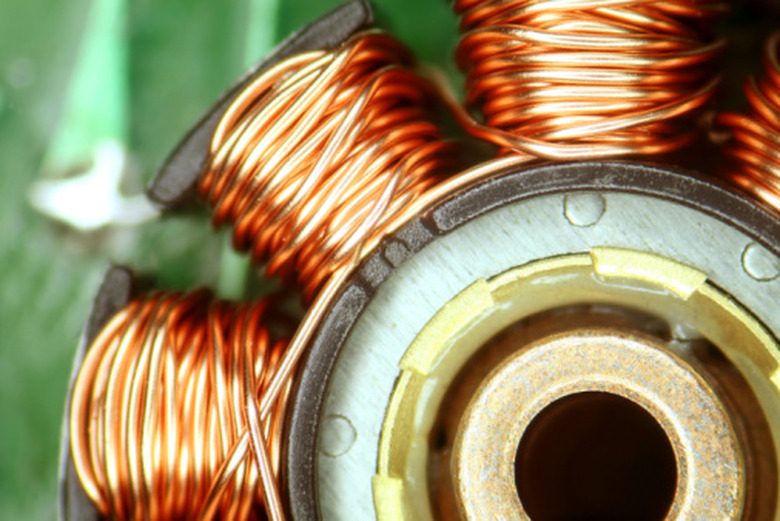

Alternating current (AC) and direct current (DC) motors employ an insulated, current-carrying coil essential to their operation. The traditional method for motor rewinding involves removing the old coil, winding a new coil and varnishing.

Removal

Removal

Old coils are removed by heating the stationary part of the motor (stator) in an oven. The stator is kept in the oven at temperature of 650 degrees Fahrenheit for at least 10 hours or until the winding insulation turns to ash.

Winding

Winding

New coils are traditionally wound by hand by a technician on a coil winding machine. The technician controls the wire tension, layering and number of turns on the coil, although there is also a mechanical counter on the machine.

Varnishing

Varnishing

The newly rewound coil is warmed in an oven, immersed in an epoxy varnish and baked in an oven at a temperature of 300 degrees Fahrenheit for at least four hours. This procedure is known as dip and bake.

Cite This Article

MLA

Dunning, David. "Motor Rewinding Procedures" sciencing.com, https://www.sciencing.com/motor-rewinding-procedures-7849573/. 24 April 2017.

APA

Dunning, David. (2017, April 24). Motor Rewinding Procedures. sciencing.com. Retrieved from https://www.sciencing.com/motor-rewinding-procedures-7849573/

Chicago

Dunning, David. Motor Rewinding Procedures last modified March 24, 2022. https://www.sciencing.com/motor-rewinding-procedures-7849573/