How To Scrap The Copper Out Of An Electric Motor

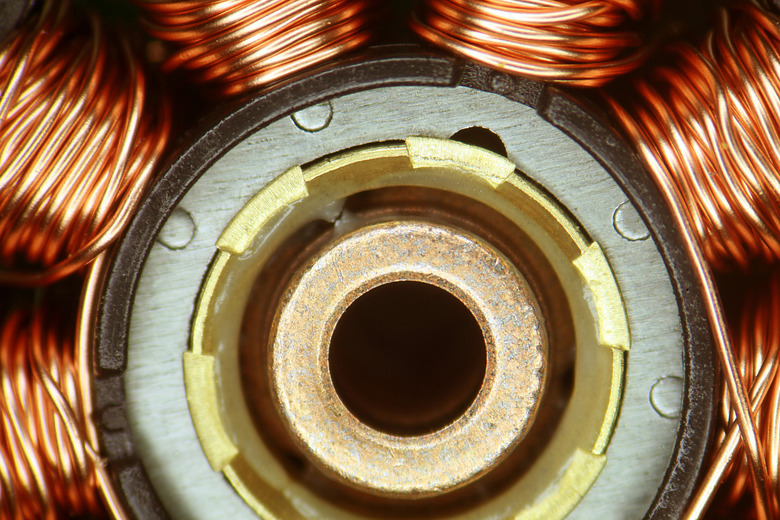

An electric motor is an electromechanical device that converts electricity into physical work. An electric motor contains several coils of electric wire that are wrapped around a common core. When voltage is applied to the leads on the electric motor, these coils become energized and produce a magnetic field; this field may then be used to turn the rotor inside the motor housing. Since most electric wire is made of copper, it is possible to harvest scrap copper from the core of an electric motor. This involves removing the coils of wire from the motor's stator.

Step 1

Use the screwdriver to loosen and remove the electric motor case screws. Remove the motor case cover from the motor frame.

Step 2

Trace the electrical lead wires to determine where the leads enter the motor housing. Use the wire cutters to cut the lead wires on the inside of the motor housing.

Step 3

Remove the coiled copper wire from the motor stator. If you wish to salvage the copper wire in one continuous piece, use the needle-nose pliers to gently unwrap the coiled wire from the stator. If you wish to remove the copper wire quickly, and if you do not need for the wire to be in one piece, you may choose to cut the coiled wire off from the stator by using the wire cutters.

Things Needed

- Electric motor

- Screwdriver

- Wire cutters

- Needle-nose pliers

Warning

Electric motors are inductive loads that store energy in the coils. To limit the risk of electric shock, make sure that the motor has not been used for at least one hour before opening the motor case.

Cite This Article

MLA

Sandoval, David. "How To Scrap The Copper Out Of An Electric Motor" sciencing.com, https://www.sciencing.com/scrap-copper-out-electric-motor-12021895/. 24 April 2017.

APA

Sandoval, David. (2017, April 24). How To Scrap The Copper Out Of An Electric Motor. sciencing.com. Retrieved from https://www.sciencing.com/scrap-copper-out-electric-motor-12021895/

Chicago

Sandoval, David. How To Scrap The Copper Out Of An Electric Motor last modified March 24, 2022. https://www.sciencing.com/scrap-copper-out-electric-motor-12021895/