What Is Vacuum Pump Oil?

If you use a vacuum pump, you need to familiarize yourself with its oil. Each pump type has its own requirements for oil, and the oil needs to be inspected and periodically replaced. These oils come in hydrocarbon, silicone and other varieties specially formulated for vacuum applications.

Description

Description

Vacuum pump oil serves as a mechanical lubricant and a medium for trapping gas molecules. It's chemically stable, unreactive to most gases and materials, and has a low-vapor pressure.

Vapor Pressure

Vapor Pressure

All substances will boil or otherwise shed molecules into a vacuum. Over time, a pressure will build up, called vapor pressure, contaminating the vacuum. Some substances, like water, boil a lot into a vacuum, others, like glass, boil very little. A clean vacuum system needs all parts, including the oil, to have vapor pressures of 10^-5 torr or lower.

Mechanical Pump

Mechanical Pump

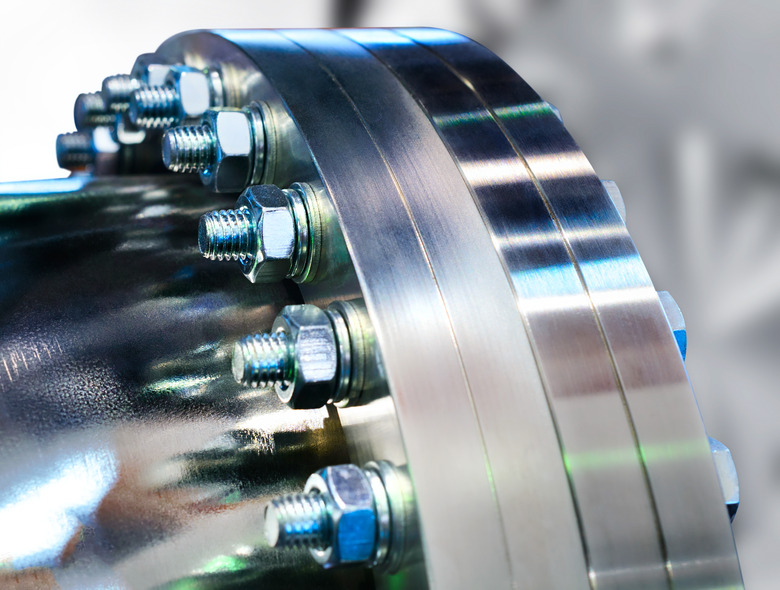

A mechanical vacuum pump has valves and rotary parts designed to pump from atmospheric pressures and below. Mechanical pumps use a hydrocarbon oil to lubricate the parts and seal the vacuum.

Diffusion Pump

Diffusion Pump

A diffusion vacuum pump collects gas molecules in a heated oil spray. It is meant to pump from low pressures only. This vacuum pump uses a silicone, hydrocarbon or perfluorinated polyether (PFPE) oil, depending on the application.

Lifetime

Lifetime

The useful lifetime of a vacuum pump's oil depends on the kind of oil, how often it's used, and the contaminants that result from use. A mechanical pump has an inspection window to check the oil's condition. If it's dark-brown, the oil needs to be replaced.

Cite This Article

MLA

Papiewski, John. "What Is Vacuum Pump Oil?" sciencing.com, https://www.sciencing.com/vacuum-pump-oil-5912297/. 23 August 2018.

APA

Papiewski, John. (2018, August 23). What Is Vacuum Pump Oil?. sciencing.com. Retrieved from https://www.sciencing.com/vacuum-pump-oil-5912297/

Chicago

Papiewski, John. What Is Vacuum Pump Oil? last modified March 24, 2022. https://www.sciencing.com/vacuum-pump-oil-5912297/